It is extremely important to have a proper cut for all HPLC tubing including PEEK tubing.

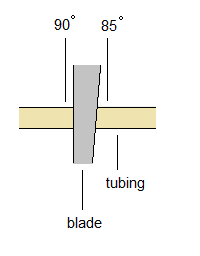

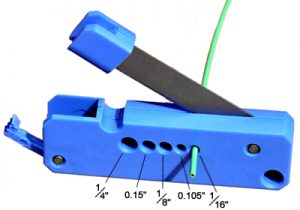

The cutting blade of the Clean-Cut90™ PEEK tubing cutter (shown below) has 2 sides. One side will be marked on the tool with an arrow, and this produces the perpendicular cut (90° angle) that you want to use. Be sure this side of the blade is facing the end of the tubing you will use. An arrow is embossed on the side that will be the cut you want to use on your instrument. It has the 90° cut. Simply insert the tubing into the appropriate hole on the side of the cutter and in one swift, downward motion, press the handle to make the cut.

The other side of the blade gives a cut with an 85° angle which is not appropriate for HPLC.

Other tubing cutters that do not employ a straight edge, never produces a perfect cut and can cause issues with HPLC results. For example, some cutters have blades that have an 86° angle on both sides. These cutters produce tubing with less than desirable cuts.

In order to get the best cut, you need to use the hole that is designated for the correct diameter tubing. The tubing cutter is equipped with holes to accommodate five different tubing ODs: 1/4″, 0.15″, 1/8″, 0.105″, and 1/16″. The tubing should fit snugly in the appropriate hole. In the picture above, the indicating arrow is not shown and is on the opposite side of the cutter displayed.

Click HERE for ordering information of the Clean Cut 90.