July 7 2022

The U-2D™ (Universal 2 Dimensional racked inserts) is not considered a 96 well plate. It is a Micro-Sample management system that fits in a 96 well plate configuration if desired.

1. Is the U-2D™ system more expensive than 2mL vials?

U-2D™ will provide more control, minimize loss and make it easier to manage their samples. What our sample management system offers is more of an upgrade in productivity and lab efficiency than a lateral cost savings.

You’ll save about 30% over certified fused insert vials and about the same price as a bag of certified, mandrel point inserts. Recall the U-2D inserts are high-precision LCMS-grade glass that resists bubble formation which is quite an upgrade for you in addition to the cost savings and other benefits.

2. What if my HPLC autosampler won’t accept 96-well plates?

You might be surprised that it does. Most modern autosamplers are flexible and can accommodate both plates and vials. Also, many customers like the U-2D plates for sample prep and then will transfer the inserts to vials. The savings in sample prep is sometimes greater than the use in the autosamplers!

Most manufacturers of HPLC’s and/or LCMS systems offer 96 well plate trays verses standard 2 mL trays. Further, most will also accommodate plates side-by-side with 2mL autosampler vials! Additionally, a standard Agilent 1200 autosampler using U-2D™ base and rack allows up to 92 more samples per bay than 2mL trays. This greatly improves efficiency all while lowering your costs.

3. Can the U-2D™ be centrifuged?

Yes. The base and rack has been tested up to 2,500 x g.

4. What advantage does silanized glass offer?

“Some samples are sensitive to vial interactions like proteins, amino acids, phenols or many other polar compounds especially biological and will interact or bind with the glass walls. Much of the interaction are the result of exposed silanols on the glass surface. Silanization (vapor phase deposition) helps eliminate this surface activity on the glass and can improve recoveries and/or sample stability.”

5. Can I use the U-2D™ system for cryo storage?

Yes. The U-2D system should perform as any typical 96 well glass insert plate. It is recommended that the base be mated with the rack but isn’t necessary.

6. Will my equipment’s liquid level sensors be compatible with the U-2D™ system?

Yes most major brands work fine including hardware equipped with sensors beneath the 96 well plate (capacitance type sensors, for example). The U-2D™ rack is designed to fit precisely with the base ensuring all inserts are in intimate contact with the polypropylene material.

7. When do I need to use the Base?

The Base is needed to vortex, centrifuge and / or where excessive heat could temporarily deform the Rack. Additionally, many equipment manufacturers detect liquid levels / presence via the needle or by sensing vertically from the top of the sample vessel; however, when mated with the Rack, the Base is engineered to function with capacitance liquid sensors as the inserts are in full vertical contact with the Base (no air gaps or pockets). Also, the Base is reusable and therefore could remain as a fixture on bench equipment, automation decks or prep stations.

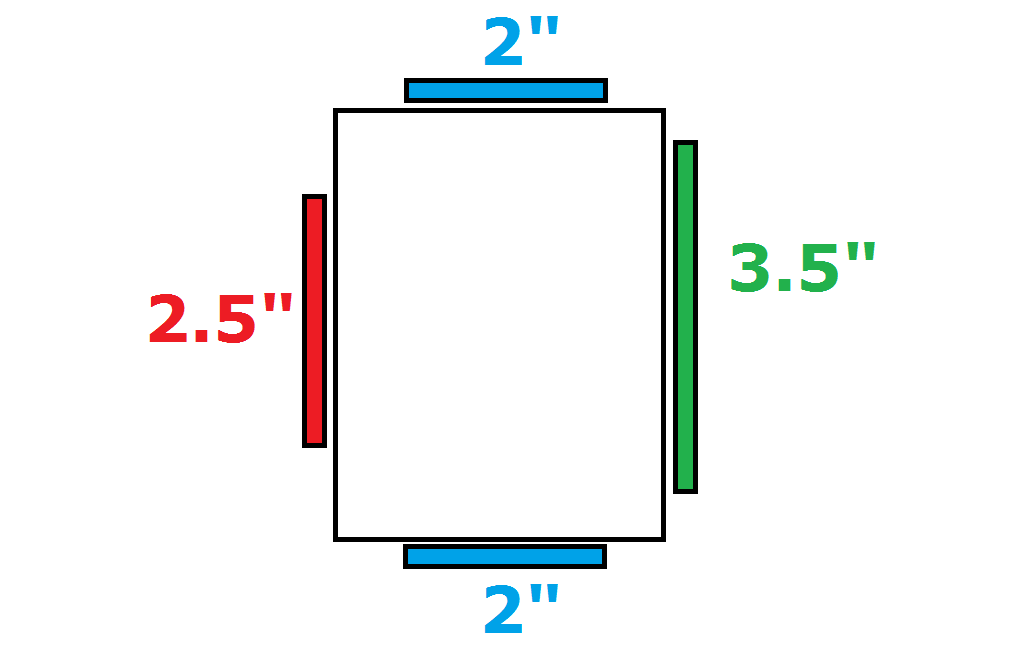

8. Can the grippers move the Rack without the Base?

Yes. There are four tabs around the Rack allowing vertical gripper access. With a slight z-axis adjustment; however, the mated Rack & Base can also be moved as a single unit similar to typical SBS-compliant 96 well plates. The end tab lengths are 2”, 2.5” on one long axis and 3.5” on the opposite axis.

9. How do I label the Rack’s tabs – regular lab markets seem to smear?

The LCMS grade polypropylene is very low surface energy resisting many inks which can smear or smudge until several minutes drying time. For instant, near odorless performance, we recommend our markers. They are available in black or red ink and perform remarkably on many difficult surfaces. Also, the asymmetrical tabs provide unique chain of custody labeling opportunities.

10. What type of vial will accept the U-2D™ glass inserts?

Standard, wide-opening 9mm 12x32mm screw top autosampler vials. However, we recommend our line of AQ™ brand of 9mm vials which are manufactured to mate precisely with the vial’s surface offering maximum performance, unmatched by anyone else.

11. What advantage does the U-2DTM offer when used with water baths for solvent reduction?

“In Rack-only mode all 96 glass inserts are available to the heat transfer medium (water) as no polypropylene or air gap exists to insulate the transfer. This allows faster, more precise thermal control across the entire array enhancing analyte loss control and improving RSDs.”

12. What else is special about the glass inserts?

The U-2D™ glass inserts are extremely precise which improves all aspects of plate handling from seal uniformity via mat or film, to vial closure performance and elimination of machine jams from profile dimensional variations. It is not uncommon for lesser quality inserts to vary slightly in profile height which can impact results if a critical depth of sample draw is required. Additionally, the glass inserts resist bubble formation which may eliminate a costly centrifuge, shake, or vortex step.

13. Can the plates be stacked?

Yes. The top surface of each Rack has four small cavities to accept the legs from another nested Rack. This feature is helpful for hotel storage, limited bench / deck space and adding stability security when manually transferring the plates from one work station to another.

14. Is the base ANSI / SLAS compliant?

Yes. The U-2D™ conforms to SBS standards and follows the ANSI / SLAS microplate standards and when the Rack and Base are mated is virtually indistinguishable from existing glass insert 96 well plates (and similar).

15. Can you name some advantages glass inserts have over plastic 96 well plates?

Glass accepts a wider variety of solvents, has virtually no absorption, has fewer leachables, enjoys superior transparency for visual acuity, is more robust for automation and faster, more uniform temperature control for your samples. Glass may open up new possibilities to improve existing methods in both speed, solvent choices and reduce MS contamination from the use of plastics.

16. I am using micro titer plates now, the cost to use the U-2D seems excessive?

U-2D™ will provide more control, minimize loss and make it easier to manage their samples. What our sample management system offers is more of an upgrade in productivity and lab efficiency than a lateral cost savings.

You’ll save about 30% over certified fused insert vials and about the same price as a bag of certified, mandrel point inserts. Recall the U-2D inserts are high-precision LCMS-grade glass that resists bubble formation which is quite an upgrade for you in addition to the cost savings and other benefits.

17. I am using organic solvents and the volatility requires I use an inert sealing mat. You do not offer one, what do you suggest?

We offer both a silicone rubber mat and ‘zone-free’ films (no adhesive is present over the insert aperture which minimizes solvent interaction with adhesives). Our evaporation data indicates the silicone mats provide virtually no water loss over a 72-hour period. Organic solvents, however, will suffer some sample loss. Currently, commercially available PTFE-coated (or laminated) mats have proven ineffective in controlling organic evaporation loss for glass insert plates; We offer chemical resistant sealing mats for use with organic solvents that are common in HPLC but cannot be used with non polar solvents. Click HERE for picture of these mats.

Click HERE for U-2D™ ordering information and pictures