When having poor chromatographic results, before you spend time troubleshooting the HPLC column, rule out other easier to fix, possibilities first. Problems you can encounter with peak shape, retention, and so on can often be traced to a component of the HPLC system. For example, consider the following real-world situation which we encountered in our laboratory.

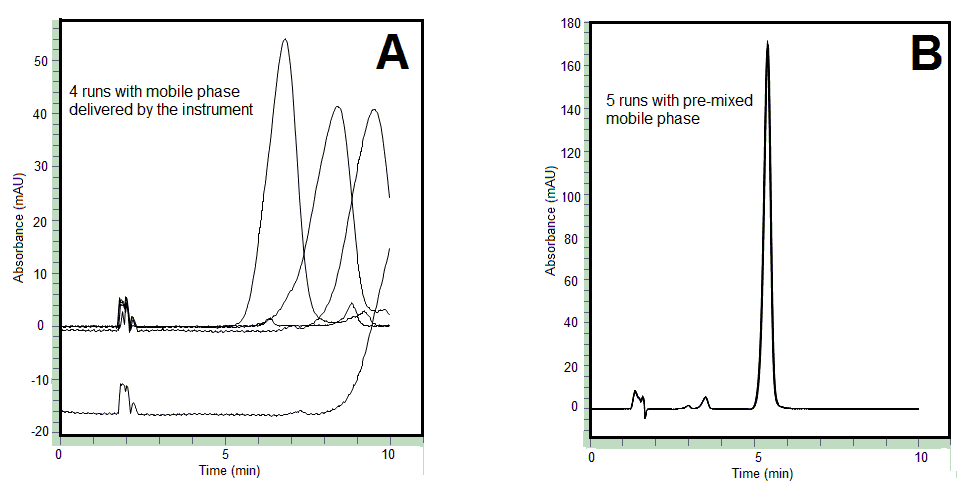

We were running an HPLC method for ethylbenzene (0.1mg/mL concentration) with a Cogent UDA™ column and observed some problems with the chromatograms (see Figure A). We noticed that our analyte peak was retained longer and longer after each injection and that the peak became broader. Was this changing chromatographic behavior due to column damage? We know the columns are very stable so we investigated other more likely possibilities first.

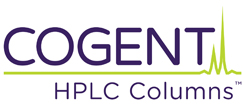

We were using a 0.5mL / minute isocratic mobile phase from two solvent reservoirs (70% solvent A, 30% solvent B). Thinking there may be a problem with one of the solvent lines, we prepared a premixed mobile phase instead and only used one mobile phase reservoir (solvent A). Under these conditions, we obtained the results in shown in Figure B. Notice how the retention time precision is now very robust and the efficiency is high. This demonstrates that the column performance is fine and the problem was with the solvent B line. Perhaps the issue was at the mixing stage, in which the solvent proportioning valve was not mixing the correct amount of solvent from the B line.

Also apparent from Figure A was a second, smaller peak that sometimes would show up in the chromatograms and sometimes would not. As before, we investigated system issues as the possible cause. It turned out that it was a problem with the injector. We were using an injection volume of 1 µL, and when we increased it to 5 µL, the peak was consistently present in every run (Figure B).

So before you blame the column, be sure to inspect everything else thoroughly:

• Check your mobile phase. Are the A and B lines connected to the correct inlet ports? Has the flow rate been calibrated for each line? Is the solvent mixer proportioning valve functioning accurately? When was the mobile phase prepared and does it need to be replaced?

• Check your method. Are you using an appropriate mobile phase/gradient for your compounds? Use an ANP gradient for polar compounds and a reversed phase one for less polar analytes. Are you operating at a proper detection wavelength for your compounds’ UV absorption properties? Before running a sequence, look through your method settings and make sure someone else who used the instrument before you didn’t accidently change anything.

• Check your sample prep. Are the analyte concentrations suitable? Ensure that overload of the column or the detector will not occur at these concentrations and dilute if necessary. Have your samples been properly filtered to remove particulate matter from entering the system and creating blockages? Have you performed percent recovery studies to demonstrate that the analytes are completely present in the final sample for analysis?

• Check your injector. Is the needle going down far enough to reach the liquid sample? Is the syringe aspirating the correct volume of sample?

This is of course not a comprehensive troubleshooting list but it can give you some idea of the type of things that can malfunction. An HPLC analysis can be complex and involves many factors so do not start with blaming the column.