Properly cutting stainless steel tubing for HPLC can be very challenging.

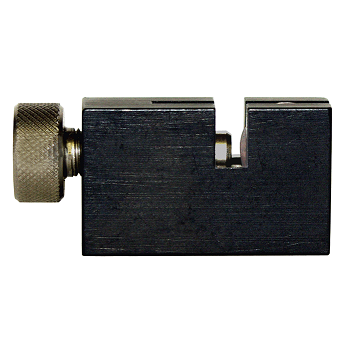

Here are some tips and instructions on cutting tubing using the MicroSolv tubing cutter, catalog number 46001-01.

- Introduce the tubing into the cutter shown below and lightly tighten the screw. If you tighten too much you will deform the tubing walls.

- Turn the cutter a few times around the tubing.

- Retighten and repeat the procedure several times.

- After a clean and distinct score in the tubing is achieved, remove the tubing from the cutter.

- Break the tubing carefully at the site of the score. It is important that the tubing is not bent or deformed at this point.

- If the tubing does not break, repeat above.

- Once the tubing is broken, use a device to ream the inside and file the outside. Remove all burrs or flares from the tubing. Make sure that the shape of the hole in the tubing is perfectly symmetrical.

Make certain that the tubing has a very perpendicular, flat break. It is extremely important to have tubing walls that are not deformed.

Note: Thin walled tubing is harder to cut properly than thick walled tubing due to the ease of deforming the tubing walls.

Note: Cutting wheel has a thickness of 0.36 mm.