How do I keep my solvents degassed on their way to the HPLC pump - FAQ

January 4, 2013

/

/

/

/

/

/

/

/

/

/

/

/

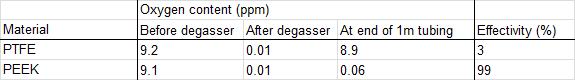

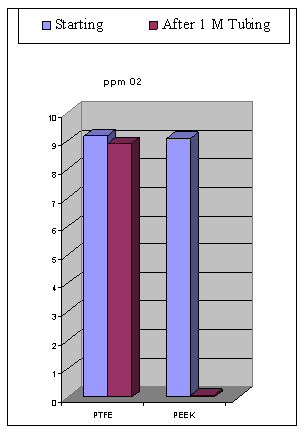

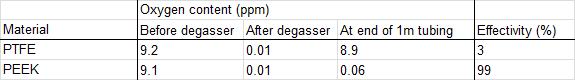

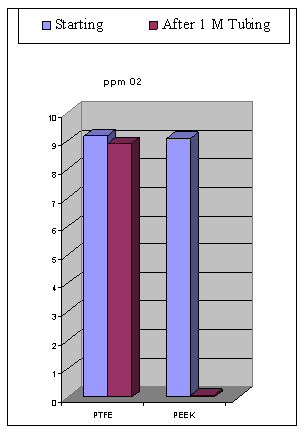

The following study was conducted on two tubing materials in order to determine which would be most suitable for keeping a degassed solvent free of air bubbles. Oxygen content was measured before introduction to the degasser, immediately after exiting the degasser, and finally after traveling through 1 meter of the tubing. From these values, effectivity is calculated and reveals PEEK tubing is far superior to PTFE but a low pressure tubing such as PFA is also acceptable. See more information on low pressure tubing: Low pressure tubing information

Many HPLC users use PTFE tubing after the degasser stage but are unaware of its re-gassing characteristics. PTFE is in fact used inside the degasser so that air bubbles are able to exit through the tubing walls while under the vacuum of the degasser. After exiting the degasser and passing through the tubing, the same principle allows for air to re-enter the tubing from the atmosphere due to the pressure difference. For this reason, PTFE should not be used after the degasser.

Conditions:

Solvent: Demineralized water at 22 °C

Flow rate: 1 mL / min

Tubing Dimensions: 1 meter length, 1/8" OD x 1/16" ID

Click HERE for tubing ordering information and pictures.

Many HPLC users use PTFE tubing after the degasser stage but are unaware of its re-gassing characteristics. PTFE is in fact used inside the degasser so that air bubbles are able to exit through the tubing walls while under the vacuum of the degasser. After exiting the degasser and passing through the tubing, the same principle allows for air to re-enter the tubing from the atmosphere due to the pressure difference. For this reason, PTFE should not be used after the degasser.

Conditions:

Solvent: Demineralized water at 22 °C

Flow rate: 1 mL / min

Tubing Dimensions: 1 meter length, 1/8" OD x 1/16" ID

Click HERE for tubing ordering information and pictures.