Why are pipettors not recommended for dispensing non aqueous liquids accurately and precisely - FAQ

March 31, 2012

/

/

/

/

/

Many of the pipettor manufacturers have identified the inadequacy of air displacement pipettors when dispensing, non-aqueous or viscous samples. The reasons why pipette manufacturers recommend that pipettors only be used for aspirating and dispensing aqueous liquids are described below.

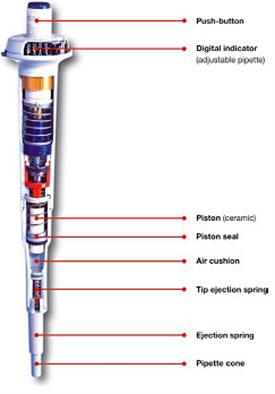

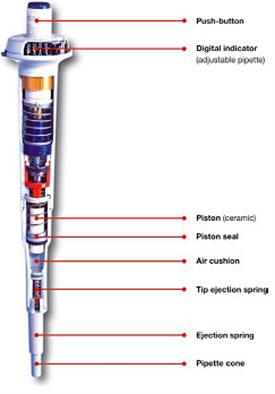

When the push-button is depressed and released the upward movement of the piston produces a partial vacuum in the pipette tip. If the pipette tip is immersed in a liquid the partial pressure will cause the liquid to be drawn into the pipette tip.

The liquid is aspirated into the tip by a cushion of air moved by the piston. This air-cushion between the liquid and the piston behaves like a spring that effectively holds the aspirated volume of liquid in the tip.

As air is elastic and can expand, the volume of air moved by the piston needs to be approximately 2%-4% greater than the aspirated volume. This expansion of air is compensated for through a correction factor that takes into consideration the volume of air and the height the volume is lifted in the pipette tip. Many aspects can influence the correctness of this compensating factor and consequently the dispensing accuracy and precision. These include variations in air pressure, air humidity, sample density and sample viscosity. These variations must be avoided to ensure dispensing accuracy is not impaired. Random changes in the elasticity of the air-cushion, which are likely to occur between aspirations, will impair the sample to sample precision of the device.

Pipettors are developed to accurately aspirate and dispense aqueous liquids. Calibration procedures for pipettors recommend they are calibrated gravimetrically using only pure water. Using liquids with a high vapor pressure will alter the elasticity of the air cushion and will hence affect the accuracy of the compensation factor. Similarly the aspiration of liquids with high viscosity or high density will influence the extent the air cushion is expanded and will also result in inaccurate dispensing.

In a positive displacement system liquid occupies the space created when the plunger is moved in the cylinder. The accuracy of aspirating and dispensing using a positive displacement device is not affected by the sample vapor pressure since there is no air cushion between the plunger and the sample. Provided the sample is aspirated at an appropriate speed the sample viscosity or density will not affect the dispensing accuracy or precision.

Above is a schematic of a typical pipette.

Air-displacement (air-cushion) pipettors are able to dispense liquid due to piston-cylinder system located in the pipettor body.When the push-button is depressed and released the upward movement of the piston produces a partial vacuum in the pipette tip. If the pipette tip is immersed in a liquid the partial pressure will cause the liquid to be drawn into the pipette tip.

The liquid is aspirated into the tip by a cushion of air moved by the piston. This air-cushion between the liquid and the piston behaves like a spring that effectively holds the aspirated volume of liquid in the tip.

As air is elastic and can expand, the volume of air moved by the piston needs to be approximately 2%-4% greater than the aspirated volume. This expansion of air is compensated for through a correction factor that takes into consideration the volume of air and the height the volume is lifted in the pipette tip. Many aspects can influence the correctness of this compensating factor and consequently the dispensing accuracy and precision. These include variations in air pressure, air humidity, sample density and sample viscosity. These variations must be avoided to ensure dispensing accuracy is not impaired. Random changes in the elasticity of the air-cushion, which are likely to occur between aspirations, will impair the sample to sample precision of the device.

Pipettors are developed to accurately aspirate and dispense aqueous liquids. Calibration procedures for pipettors recommend they are calibrated gravimetrically using only pure water. Using liquids with a high vapor pressure will alter the elasticity of the air cushion and will hence affect the accuracy of the compensation factor. Similarly the aspiration of liquids with high viscosity or high density will influence the extent the air cushion is expanded and will also result in inaccurate dispensing.

In a positive displacement system liquid occupies the space created when the plunger is moved in the cylinder. The accuracy of aspirating and dispensing using a positive displacement device is not affected by the sample vapor pressure since there is no air cushion between the plunger and the sample. Provided the sample is aspirated at an appropriate speed the sample viscosity or density will not affect the dispensing accuracy or precision.