Technical Bulletin: Autosampler Vial Dimensional Standards and Internal Bottom Consistency

Precision Matters: Why Internal Geometry Is Just as Critical as External Fit

High-performance liquid chromatography (HPLC) autosamplers rely on precise vial geometry to ensure accurate, reproducible injections and to protect sensitive instrumentation. While most instrument manufacturers specify external vial dimensions—such as height, neck diameter, shoulder profile, and outer width—to prevent mechanical jamming, internal vial geometry is equally critical, particularly for autosamplers that utilize bottom-sensing injection protocols.

Understanding Autosampler Behavior

Modern autosamplers often include a startup routine that "learns" the internal bottom position of the vial. This is done to:

- Prevent needle damage by avoiding contact with the vial bottom

- Ensure consistent sample draw depth

- Optimize injection volume reproducibility

This process depends on the internal bottom height being consistent across all vials used in a sequence.

The Problem with Inconsistent Vial Bottoms

Many commercially available autosampler vials—especially low-cost options—are manufactured with a focus solely on external "fit and form." These vials often exhibit:

- Variable internal bottom profiles, such as convex or uneven surfaces

- Lack of internal dimensional control, leading to inconsistent needle positioning

- Increased risk of injection errors, skipped injections, or even needle damage in older systems

Such inconsistencies can compromise data integrity and increase maintenance costs.

The RSA™ and AQ™ Advantage

RSA™ and AQ™ brand vials and inserts are engineered to meet both external and internal dimensional specifications. These vials are:

- Manufactured with tight tolerances for internal bottom height

- Designed in collaboration with leading HPLC instrument manufacturers

- Subjected to rigorous quality control, including dimensional verification and functional testing

This ensures compatibility with autosamplers that rely on bottom-sensing logic and provides Consistency Assurance across batches.

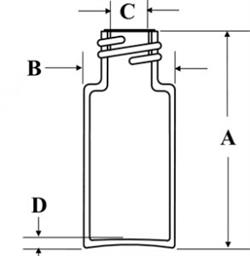

Critical Dimensional Parameters for Autosampler Vials

| Dimension | Description |

|---|---|

| A | Overall Height |

| B | Outer Diameter |

| C | Internal Opening Diameter |

| D ** | Internal Bottom Height (critical for needle positioning) |

Conclusion

For laboratories using advanced autosamplers, vial selection must go beyond external specifications. ** Internal bottom consistency is essential ** for protecting instrumentation and ensuring reliable, reproducible results—especially in high-throughput or regulated environments.

RSA™ and AQ™ vials are engineered to meet these demands, offering a level of precision that supports today’s most sophisticated analytical workflows.

Click HERE for RSA brand autosampler vials technical and ordering information