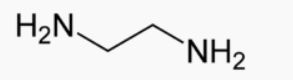

Ethylenediamine is known to associate with metals, forming organometallic complexes.

In terms of HPLC runs, this can present problems for analyte peak shape. Most commercial HPLC systems will most likely have some trace metals present that can be problematic. These metals can come from many sources such as the glass bottles, the pump components, columns etc. What you can do to mitigate this somewhat is add 5–10 uM EDTA to the mobile phase and/or sample diluent. The metals present will chelate with EDTA instead of ethylenediamine, thereby alleviating the problem.

HINT: Make sure your mobile phase is acidic so that any residual silanols on the HPLC column are somewhat neutralized as poor peak shape could also come from electrostatic adsorption with silanols; 0.1% formic acid is a good choice. If you are not using LC-MS, 0.1% TFA is a good choice as well.

Another check is that your column is not overloaded by using a low injection volume/analyte concentration.